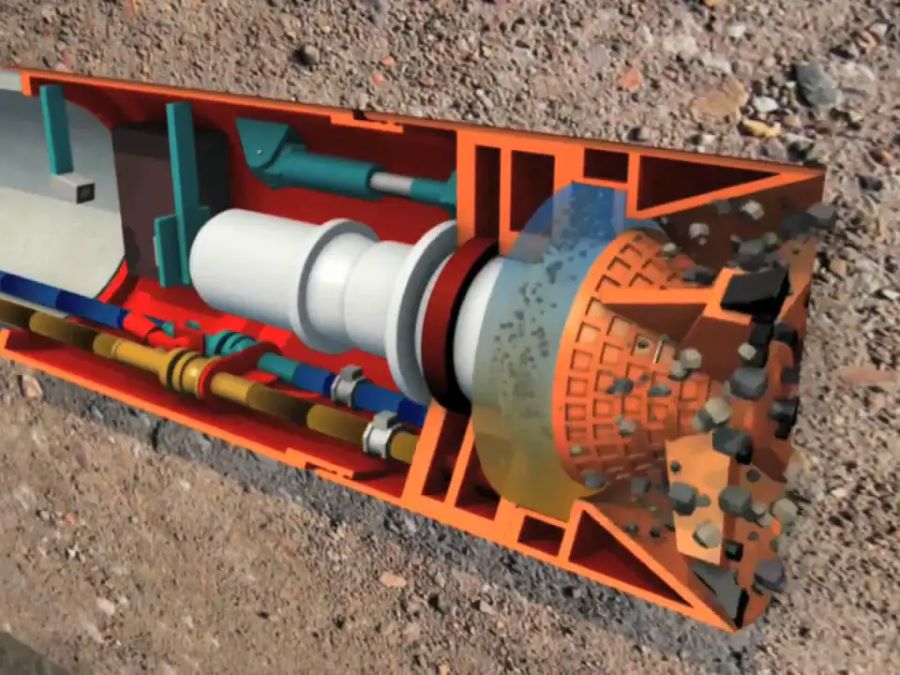

Small tunnel boring machines (TBMs) are designed for constructing tunnels with relatively smaller diameters,typically ranging from 1 meter to 5 meters in diameter, are compact versions of their larger counterparts, typically used for projects such as utility tunnels, sewer lines, water pipelines, and small transportation tunnels. . They are engineered to navigate through tight spaces, operate in confined environments, and handle complex geologies. The design of a small TBM includes a cutting head equipped with disc cutters or teeth to excavate the tunnel face, a support system to maintain the tunnel stability, and a conveyor system to remove the excavated material.

Types of Small Tunnel Boring Machines

1. Earth Pressure Balance (EPB) TBM

- Uses the excavated material to balance the pressure at the tunnel face.

- Suitable for soft ground conditions with variable water content.

- Commonly used in urban areas to minimize surface settlement.

2. Slurry Shield TBM

- Uses a pressurized slurry to stabilize the tunnel face.

- Ideal for soft ground and high water pressure conditions.

- Slurry is separated and recycled at the surface.

3. Rock TBM

- Designed for hard rock conditions.

- Uses disc cutters to fracture and grind the rock.

- Efficient in stable rock formations with minimal water ingress.

Advantages of Small TBMs

1. Precision and Control

- High precision in alignment and grade control.

- Minimal disruption to the surface and existing structures.

2. Safety

- Provides a safe working environment for workers.

- Reduces the risk of collapses and ground instability.

3. Efficiency

- Continuous excavation and lining installation.

- Higher advance rates compared to traditional methods.

4. Environmental Impact

- Reduced noise and dust generation.

- Minimizes environmental disturbance and surface disruption.

Applications

Small TBMs find applications in a variety of sectors due to their ability to construct tunnels with high precision and minimal disruption. Here are some of the primary areas where small TBMs are employed:

1. Water and Sewer Systems: Small TBMs are often used to construct tunnels for water supply, sewage, and drainage systems. Their compact size enables them to navigate through urban environments without causing significant surface disturbance.

2. Utility Lines: For laying cables, pipelines, and other utility lines, small TBMs offer a non-intrusive solution that can minimize the impact on traffic and the environment.

3. Mining Operations: In the mining industry, small TBMs are utilized for the excavation of access tunnels, ventilation shafts, and ore extraction tunnels.

4. Transportation: They are used for the construction of small-scale subway lines, pedestrian tunnels, and underground passages.

Small tunnel boring machines play a vital role in modern tunneling projects, offering a combination of efficiency, safety, and minimal environmental impact. They are essential tools for constructing small-diameter tunnels in various ground conditions, providing reliable solutions for urban infrastructure and utility projects.