Are tunnel boring machines reused?

Yes, tunnel Boring Machines (TBMs) are indeed reused, but depends on various factors, including the machine's condition, the requirements of the new project, economic considerations, and logistical challenges.

When a TBM completes its job, it is typically disassembled at the tunnel exit and then transported to a new location for another project. However, before it can be reused, the machine often undergoes significant refurbishment and customization to suit the specific geological conditions and tunnel dimensions of the new project. This process can include replacing worn parts, upgrading systems, and sometimes altering the TBM's design to better fit the new tunnel's requirements.

The decision to reuse a TBM depends on several factors, including the cost of refurbishment versus building a new machine, the urgency of the new project, and the compatibility of the TBM with the new tunnel's characteristics. In some cases, TBMs are sold or leased to other contractors or projects, which can be a cost-effective solution for projects that require tunneling but do not justify the expense of purchasing a new machine.

Tunnel boring machines (TBMs) can be reused, but the feasibility and cost-effectiveness of reusing a TBM depend on several factors:

1. Condition of the Machine

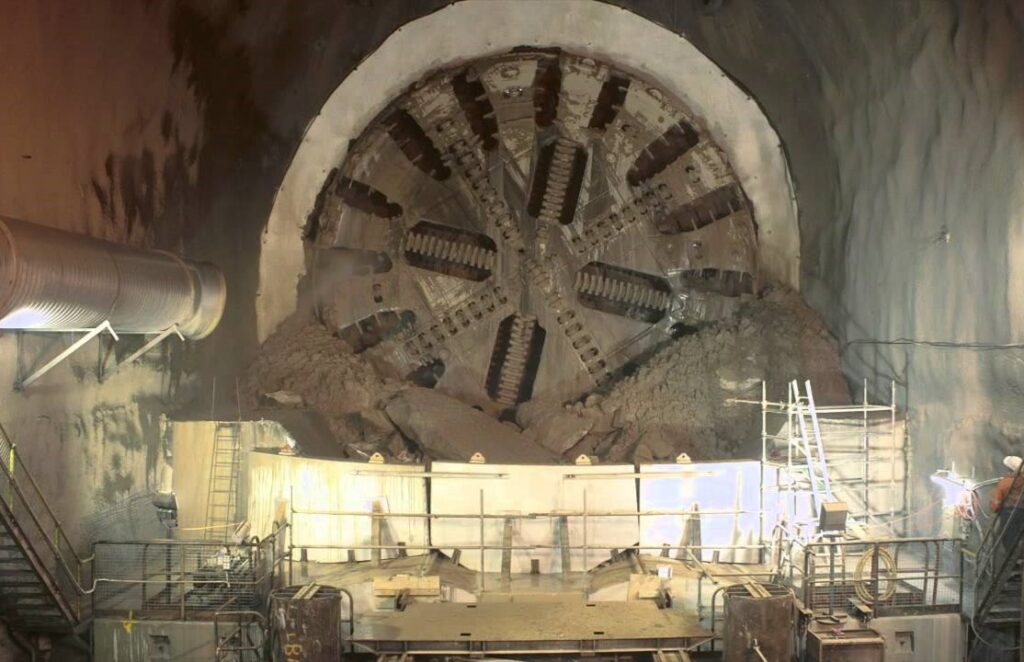

After completing a project, the TBM needs to be thoroughly inspected and possibly refurbished. This includes replacing worn parts like cutterheads, bearings, and seals. If the machine is in good condition, it can be reused for another project.

2. Compatibility with New Project Requirements

TBMs are often custom-built for specific projects, taking into account the geological conditions, tunnel diameter, and other factors. If a new project has similar requirements, the TBM can be reused with minimal modifications. However, if the conditions differ significantly (e.g., different soil or rock type, different tunnel diameter), the TBM may require substantial modification or it may not be suitable for reuse at all.

3. Economic Considerations

Refurbishing and adapting a TBM for a new project can be costly. The decision to reuse a TBM often hinges on whether the cost of refurbishment is less than the cost of purchasing a new machine. Additionally, the time required for refurbishment can be a critical factor, especially if project timelines are tight.

4. Transportation and Logistics

Disassembling, transporting, and reassembling a TBM can be complex and expensive, especially for large machines. The logistics of moving a TBM from one site to another can affect the decision to reuse it.

5. Regulatory and Ownership Issues

Ownership of the TBM can also play a role. Some TBMs are owned by the construction companies that use them, while others are rented or leased. The terms of these agreements can influence whether a TBM is reused or not.

6. Examples of Reuse

Reusing TBMs is not uncommon in large-scale infrastructure projects. For example, the TBMs used in the construction of the London Crossrail project were refurbished and reused for different sections of the project. Similarly, the TBM used in the Seattle Alaskan Way Viaduct Replacement Tunnel (nicknamed "Bertha") was extensively refurbished after it broke down and was then reused to complete the project.

TBMs are reused frequently, but the process involves significant logistical and engineering challenges to prepare them for new tunneling tasks. The reuse of these machines not only saves resources but also supports the sustainability of large-scale infrastructure projects by minimizing waste and reducing the environmental impact of manufacturing new TBMs.