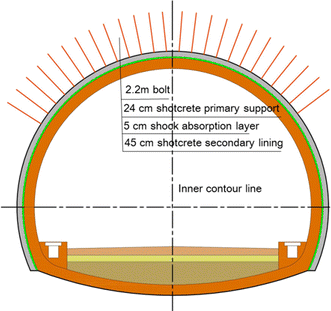

Composite lining usually refers to a composite support structure formed by constructing the initial support first and then constructing the secondary lining in time according to the deformation of the surrounding rock and the support effect in tunnel engineering.

This structure is widely used in modern tunnels and underground projects and has the following advantages and disadvantages:

I. Advantages

1. Strong bearing capacity

- The initial support and the secondary lining jointly bear the load, which can adapt to complex geological conditions and large surrounding rock pressure. The initial support can seal the surrounding rock in time to prevent excessive deformation of the surrounding rock, and the secondary lining can provide sufficient strength and stability in the later stage.

- For example, in areas with weak surrounding rock, the composite lining can effectively control the deformation of the surrounding rock and ensure the safety of the tunnel.

2. Good waterproof performance

- A waterproof layer can be set between the two layers of lining to effectively prevent groundwater from seeping into the tunnel. The waterproof layer between the primary support and the secondary lining can be made of waterproof board, waterproof coating and other materials to form a complete waterproof system.

- Taking Shenzhen as an example, the groundwater is relatively abundant. The good waterproof performance of the composite lining can ensure the dryness of the tunnel interior and reduce the maintenance cost during the operation of the tunnel.

3. Great construction flexibility

- The parameters of the primary support and secondary lining can be adjusted according to different geological conditions and construction requirements. In areas with good geological conditions, the thickness and strength of the primary support can be appropriately reduced to speed up the construction progress; in areas with poor geological conditions, the primary support and secondary lining can be strengthened to ensure the safety of the tunnel.

- At the same time, the construction of the composite lining can adopt a variety of methods, such as the step method, the full section method, etc., to adapt to different tunnel sections and construction conditions.

4. Good durability

- The secondary lining usually uses materials with good durability such as concrete, which can effectively resist the influence of factors such as groundwater and chemical corrosion, and extend the service life of the tunnel.

- In coastal cities like Shenzhen, tunnels face problems such as seawater erosion, and the durability advantage of composite lining is more obvious.

II. Disadvantages

1. Complex construction process

- Composite lining requires initial support and secondary lining to be carried out successively, with more construction processes and a longer construction period. During the construction process, multiple blasting, support and concrete pouring operations are required, which increases the construction difficulty and safety risks.

- For example, the construction of initial support requires drilling, installation of anchor rods, shotcrete and other processes, while the construction of secondary lining requires template installation, steel bar binding, concrete pouring and other processes, all of which require a lot of time and manpower.

2. High cost

- Because composite lining requires the use of more materials and equipment, the construction cost is high. Initial support usually uses materials such as anchor rods and shotcrete, while secondary lining uses materials such as concrete, and the prices of these materials are relatively high. In addition, the construction of composite lining requires the use of large-scale mechanical equipment, such as rock drilling trolleys, concrete spraying machines, lining trolleys, etc., and the rental and maintenance costs of these equipment are also high.

- In economically developed areas such as Shenzhen, land resources are tight and tunnel construction costs are high, and the cost problem of composite lining is more prominent.

3. Difficult quality control

- The quality control of composite lining is difficult, and the construction quality of initial support and secondary lining needs to be strictly controlled. The quality of initial support directly affects the stability and safety of the tunnel, and the quality of secondary lining directly affects the waterproof performance and durability of the tunnel.

- During the construction process, it is necessary to strictly test the length, spacing, thickness and strength of the anchor rods to ensure that the quality of the initial support meets the requirements. At the same time, it is necessary to strictly control the concrete mix ratio, pouring quality, and laying quality of the waterproof board of the secondary lining to ensure that the quality of the secondary lining meets the requirements.

Composite lining is a widely used support form in tunnels and underground projects. It has the advantages of strong adaptability, high safety and good economy, but it also has disadvantages such as long construction period, high initial support cost and high construction technology requirements. In specific projects, the lining scheme should be reasonably selected and optimized according to geological conditions and project requirements.