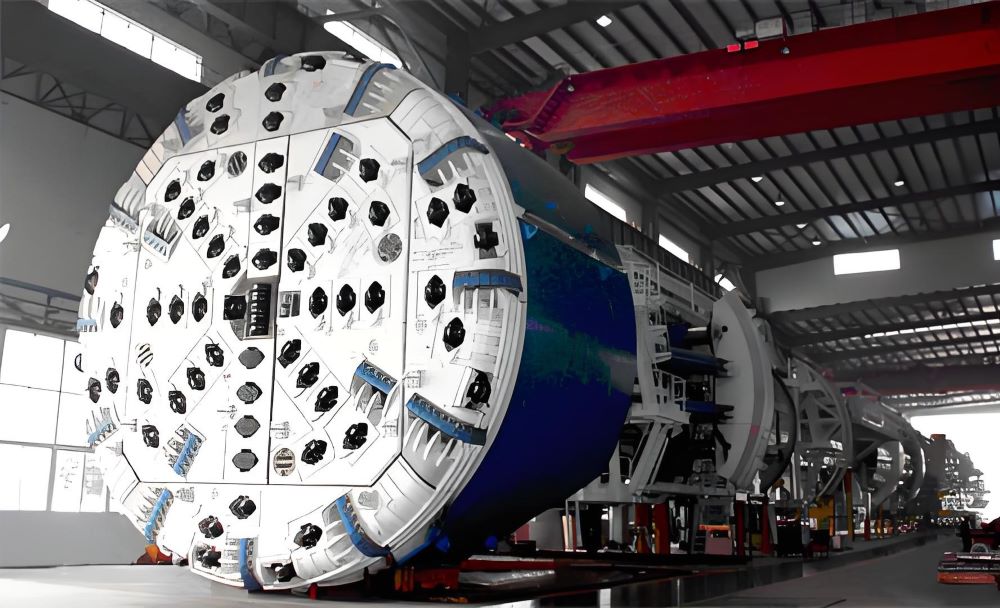

What is a tunnel boring machine?Types of Tunnel Boring Machines!A Tunnel Boring Machine (TBM), also known as a "mole," is a large, sophisticated piece of machinery used to excavate tunnels through various types of soil and rock. These machines are at the forefront of modern tunneling technology and are capable of cutting through solid rock, as well as soft soil, with incredible efficiency. They are designed to create tunnels with a smooth, circular cross-section, making them ideal for the construction of underground railways, water conduits, roadways, and utility lines.

Types of Tunnel Boring Machines

1. Earth Pressure Balance (EPB) TBMs

- Usage: These are commonly used in soft ground conditions, including clays, silts, and sands.

- Function: EPB TBMs maintain a balance of pressure in the cutting chamber to stabilize the face of the excavation, preventing ground collapse and controlling the flow of excavated material.

2. Slurry Shield TBMs

- Usage: Suitable for soft to hard ground conditions, particularly in areas where groundwater control is critical.

- Function: These machines use a slurry to remove excavated material and to stabilize the tunnel face. The slurry is a mixture of water and bentonite or another polymer that helps to maintain the stability of the tunnel face and to transport the cut material to the surface.

3. Hard Rock TBMs (also known as Rock TBMs or Disc TBMs)

- Usage: These are used in solid rock conditions.

- Function: Hard Rock TBMs are equipped with disc cutters or roller cutters that break the rock by compression and shearing forces. The broken rock is then conveyed out of the tunnel through a system of conveyors.

4. Mix Shield TBMs

- Usage: Ideal for mixed ground conditions that include both soil and rock.

- Function: Mix Shield TBMs combine features of both EPB and Hard Rock TBMs. They can switch between modes depending on the ground conditions, making them versatile for a wide range of geological conditions.

5. Micro TBMs

- Usage: Used for small diameter tunnels, typically less than 1 meter in diameter.

- Function: These are smaller versions of the larger TBMs and are used for utility tunnels, such as pipelines, conduits, and sewers.

6. Shielded TBMs

- Usage: These are used in unstable ground conditions or where tunnel stability is a concern.

- Function: Shielded TBMs provide a shielded tunneling environment, protecting the workers and equipment from ground collapse and ensuring the stability of the tunnel as it is being excavated.

7. Open TBMs

- Usage: Primarily used in stable ground conditions where there is no risk of tunnel collapse.

- Function: These machines do not have a shield around the cutting wheel, allowing for a more direct and often faster excavation process. However, they require the ground to be stable enough to support the tunnel without immediate lining.

8. Double Shield TBMs

- Usage: Used in very stable ground conditions, typically in hard rock.

- Function: Double Shield TBMs are designed for the efficient installation of precast concrete segments. They have two shields: the cutting shield and a second shield for the installation of the segments.

9. Crossover TBMs

- Usage: Designed for variable ground conditions.

- Function: These TBMs can adapt to changing geological conditions by modifying their cutting tools and support systems. They are particularly useful in tunnels that pass through different types of ground.

TBMs come in various sizes and designs, depending on the specific requirements of the tunneling project. They can range from small machines, a few meters in diameter, used for utility tunnels, to massive machines that can be over 15 meters in diameter, used for large-scale infrastructure projects. The heart of a TBM is the cutting wheel, or shield, which is located at the front of the machine. This shield is equipped with a series of cutting tools that grind or slice through the ground as the machine advances.

As the TBM cuts through the ground, it simultaneously removes the excavated material and supports the tunnel's newly formed walls to prevent collapse. This is achieved through the use of hydraulic jacks that push the machine forward and a system of support structures, such as concrete segments or sprayed concrete, that are installed immediately behind the cutting shield to line the tunnel walls.

One of the key advantages of using a TBM is the ability to excavate tunnels with minimal disruption to the surface and the environment. This makes them particularly suitable for urban areas where traditional drilling and blasting methods would cause significant disturbance. Additionally, TBMs can operate continuously, 24 hours a day, which allows for faster tunneling compared to traditional methods.

Despite their size and complexity, TBMs require a high level of precision and engineering expertise to operate effectively. Skilled operators must monitor and control the machine's progress, adjusting the cutting force and angle to match the ground conditions and ensure the tunnel's stability and accuracy. The use of advanced sensors and computer systems helps to guide the TBM through the earth with remarkable precision.

In summary, a Tunnel Boring Machine is a powerful and sophisticated tool that revolutionizes the way tunnels are constructed. These machines offer a safer, faster, and more environmentally friendly alternative to traditional tunneling methods, making them an essential component of modern infrastructure development.