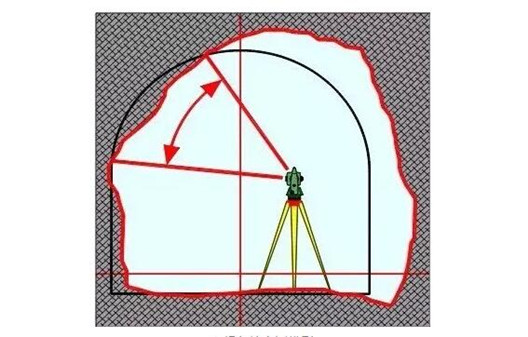

What is under excavation? Under excavation refers to the situation where the excavation section is smaller than the designed section during the construction of tunnels, mining, earthwork and other projects. Let's talk about the main causes and treatment methods of under excavation.

I. The main causes of under excavation are as follows:

1> Measurement

1. Measurement error:

- The measurement instrument is not accurate enough, resulting in inaccurate measurement data, which leads to deviations in excavation control. For example, some old measurement instruments may have reduced accuracy after long-term use.

- The measurement personnel operate irregularly, such as reading errors and unreasonable measurement point layout. For example, when arranging measurement points, the changes in terrain are not fully considered, resulting in the measurement results not accurately reflecting the actual situation.

2> Construction

1. Inadequate performance of excavation equipment:

- The power and excavation force of equipment such as excavators and rock drills are insufficient, and excavation cannot be carried out completely according to the design requirements. For example, under hard rock geological conditions, small excavators may not be able to reach a sufficient excavation depth.

- Equipment aging and severe wear affect excavation accuracy. Equipment that has been used for a long time may have problems such as tool wear and hydraulic system failure, resulting in poor excavation results.

2. Improper construction technology:

- Unreasonable blasting parameters, such as too little explosives and unreasonable blasthole arrangement. Insufficient explosives may not be able to fully crush the rock, resulting in under-excavation; too large or too small blasthole spacing will also affect the blasting effect.

- The excavation sequence is unreasonable, and excavation is not carried out according to the principle of top-down, layered and segmented, which is easy to cause local under-excavation. For example, in tunnel excavation, if the bottom is excavated first and then the top, the top rock may not fall completely, resulting in under-excavation.

3. Low technical level of construction personnel:

- The operator's mastery of the equipment is not enough and cannot accurately control the excavation size. For example, the excavator driver is inexperienced and cannot accurately judge the excavation depth and width during the excavation process.

- The construction personnel have a weak sense of quality and ignore the excavation quality in order to catch up with the progress. In some projects, construction workers may not strictly follow the design requirements to excavate in order to complete the task as soon as possible, resulting in under-excavation.

3> Geology

1. Complex geological conditions:

- The hardness of the rock is uneven, and some hard rock areas are difficult to excavate in place. For example, in tunnel construction, when encountering hard rocks such as granite and soft rocks such as mudstone alternately, the hard rock part is prone to under-excavation.

- Complex geological structures, such as faults and folds, affect the excavation effect. The rocks near the fault zone may be broken and loose, making it difficult to control the excavation size; the rocks in the fold area may be difficult to excavate due to uneven force.

2. Groundwater influence:

- Abundant groundwater will soften the rock, reduce its strength, and increase the difficulty of excavation. At the same time, groundwater may also cause the excavation surface to collapse, affecting the excavation accuracy.

- Geological disasters such as water gushing and mud will seriously interfere with construction, making it impossible to carry out excavation normally, and easily causing under-excavation.

II. There are several main methods for dealing with under excavation:

1. Supplementary excavation: Excavate the under excavation part again to make it reach the cross-sectional size required by the design. Supplementary excavation can be carried out manually or mechanically.

2. Blasting: If the rock in the under excavation part is hard, blasting can be used for treatment. However, during blasting, attention should be paid to controlling the amount of explosives and the blasting range to avoid damage to the surrounding structures.

3. Sprayed concrete: For some small-scale under excavations, sprayed concrete can be used to repair and make the surface smooth.

4. Strengthen monitoring: In the process of dealing with under excavation, it is necessary to strengthen the monitoring of surrounding structures to ensure that there will be no adverse effects on surrounding structures during the treatment process.

III. The following points should be noted when dealing with under excavation:

1. Ensure safety: When dealing with under excavation, ensure the safety of construction personnel and take necessary protective measures.

2. Strictly handle in accordance with design requirements: The cross-sectional size and shape after treatment should meet the design requirements.

3. Control quality: The treated part should be firmly connected to the surrounding structure, the surface should be smooth, and the quality should meet the relevant standards.

4. Timely processing: When under-excavation is discovered, it should be processed in a timely manner to avoid affecting the progress and quality of the project.