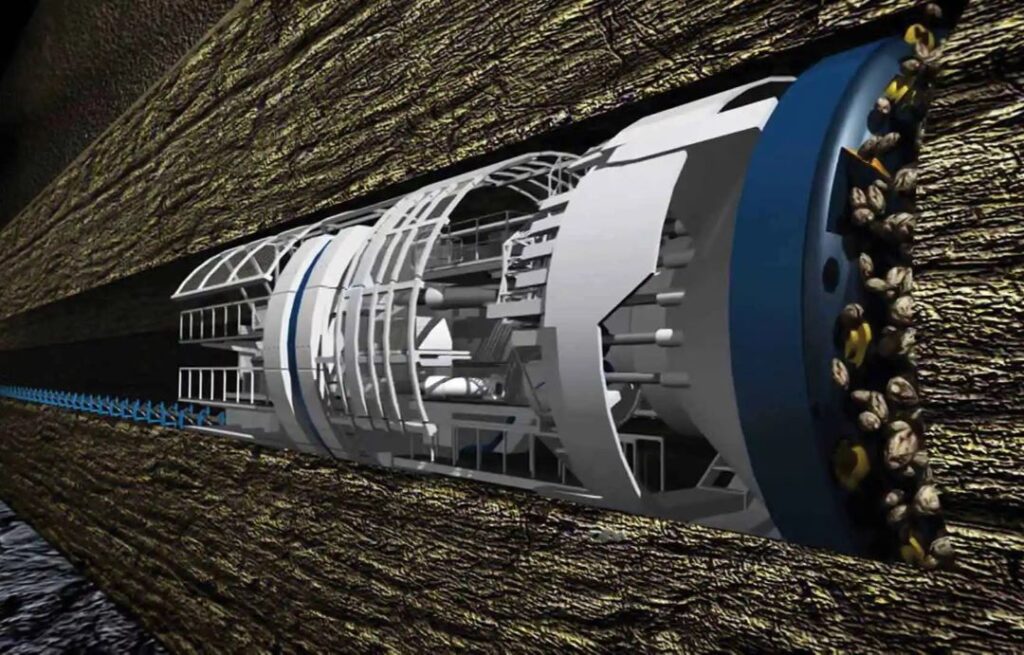

In the operation of a tunnel boring machine (TBM), elevated oil temperatures can be attributed to several factors that are inherent to the demanding environment and operational requirements of these massive machines. Understanding why oil temperatures rise in TBMs is crucial for maintaining their efficiency, safety, and longevity.

Reasons for high oil temperature of tunnel boring machine

1. Intense Mechanical Workload

Tunnel boring machines perform an immense amount of work, cutting through solid rock or soil under various pressures. The continuous movement of the cutterhead, the thrust exerted by the hydraulic jacks, and the operation of other mechanical components generate significant heat due to friction and power conversion inefficiencies.

2. Hydraulic Systems Complexity

Hydraulic systems are integral to the functioning of TBMs, powering many critical operations such as the cutterhead rotation, shield advancement, and auxiliary equipment. These systems operate at high pressures and flow rates, which can lead to substantial heat generation from fluid friction within the system.

3. Limited Cooling Capacity

In the confined space of a tunnel excavation, there is limited air circulation, reducing the natural cooling effect on the TBM's exterior surfaces. Additionally, the use of water for cooling purposes might be restricted due to concerns about electrical components and potential damage to the surrounding geology.

4. Insulation Effects

When operating deep underground, the ambient ground temperature increases with depth. This thermal insulation can exacerbate heat retention around the TBM, making it harder for heat generated during operation to dissipate naturally.

5. Electrical Components

Various electrical components used in the TBM—motors, generators, transformers, and control systems—also contribute to heat generation. Electrical inefficiencies and resistive heating add to the overall thermal load.

6. Hydraulic System Issues: Faulty pumps, valves, or cylinders in the hydraulic system can create excessive friction, increasing heat production and raising the oil temperature.

7. Excessive Friction or Wear: If internal components of the tunneling machine are worn or damaged, it can cause increased friction, which in turn generates more heat, causing the oil temperature to rise.

8. Ambient Temperature: High external temperatures or poor ventilation around the machine can exacerbate the issue, as the environment makes it harder for the cooling system to regulate the oil's temperature.

Management Strategies

To mitigate high oil temperatures in TBMs:

- Enhanced Cooling Systems: Implement more efficient cooling mechanisms, possibly involving advanced heat exchangers or coolant fluids designed to withstand harsh conditions.

- Regular Maintenance: Frequent inspection and maintenance of hydraulic systems and seals can prevent leaks and reduce unnecessary heat generation.

- Optimized Design: Incorporating design elements that facilitate better airflow and heat dissipation can improve thermal management without compromising structural integrity.

- Monitoring and Control: Utilizing sensors to monitor oil temperature continuously allows for proactive adjustments to operational parameters before overheating becomes problematic.

Monitoring and maintaining the hydraulic system regularly can help prevent high oil temperature and prolong the machine's operational life.