A drilling jumbo is a specialized piece of equipment used in mining, tunneling, and underground construction to drill holes in rock or other hard surfaces. The output of a drilling jumbo typically refers to the volume of rock or material that can be drilled and prepared for blasting or removal within a specific timeframe, often expressed in cubic meters per hour or per shift.

Factors Affecting Drilling Jumbo Output:

1. Drilling Speed: The rate at which the jumbo drills holes into the rock, usually influenced by rock hardness, hole diameter, and drill bit type.

2. Hole Depth and Diameter: Deeper and wider holes take more time, impacting overall productivity.

3. Rock Type and Condition: Harder rock reduces drilling efficiency, while fractured or weak rock might speed it up.

4. Number of Booms: Jumbos often come with multiple booms (arms), allowing for simultaneous drilling. More booms typically increase output.

5. Operator Skill: Experienced operators can manage the machine more efficiently, improving overall performance.

6. Shift Duration: Longer shifts with fewer interruptions naturally result in more drilled meters.

Calculation of Drilling Jumbo Output:

To calculate the output of a drilling jumbo, you can follow these steps:

1. Determine the number of holes drilled in a shift.

- For example, if the jumbo drills 100 holes per shift.

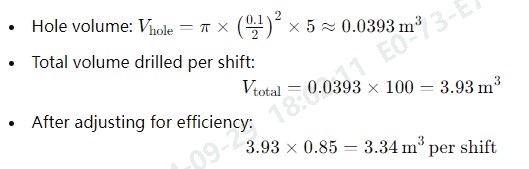

2. Calculate the volume of each hole based on its diameter and depth:

3. Total volume per shift:

4. Adjust for Efficiency:

- Factor in machine downtime, rock fragmentation efficiency, and other variables like the time to reposition the machine.

For instance, if you drill 100 holes per shift with a diameter of 0.1 meters and a depth of 5 meters, and considering 85% efficiency:

This is a basic estimation. You would need actual machine specifications and site conditions for a precise calculation.