How fast can a tunnel boring machine drill?The drilling speed of a tunnel boring machine can vary significantly depending on several factors. Generally, tunnel boring machines can drill at speeds ranging from a few meters to several tens of meters per day.

The speed is influenced by factors such as the type of rock or soil being excavated, the hardness of the material, the diameter of the tunnel, and the power and specifications of the specific tunnel boring machine. In softer ground or soil, the drilling speed may be relatively faster, while in hard rock formations, the progress can be much slower.

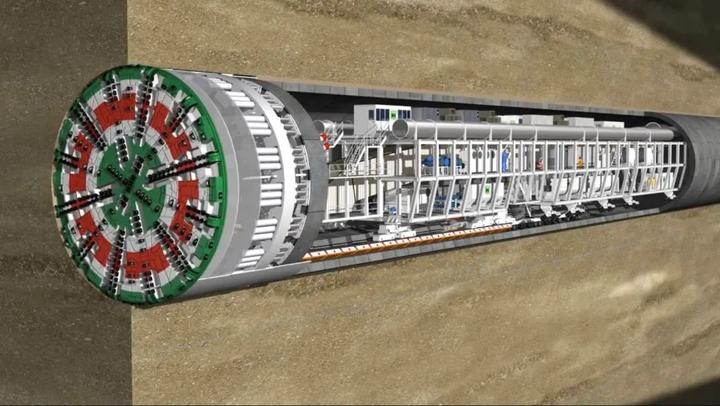

Types of TBMs

1. Hard Rock TBMs : These machines use rotating disc cutters to grind through hard rock formations. Their drilling speeds typically range from 0.5 meters per hour (m/h) up to about 20 m/h under optimal conditions.

2. Soft Ground TBMs : Also known as earth pressure balance (EPB) or slurry shield machines, these are designed for softer ground conditions like clay, silt, and sand. They can achieve higher speeds than their hard rock counterparts due to the nature of the material they cut through. Soft ground TBMs can operate at rates between 3 m/h to sometimes even exceeding 30 m/h in ideal scenarios.

Factors Influencing Speed

- Geological Conditions : Hardness, density, and composition of the geological medium significantly impact a TBM’s drilling rate. Softer materials allow faster progress.

- TBM Design : Different designs feature varying cutterhead configurations, drive power, and thrust capabilities, all affecting the machine's efficiency.

- Maintenance and Operations : Frequent maintenance checks and skilled operation ensure optimal performance. Downtime for repairs or adjustments can slow overall project timelines.

- Support Systems : Efficient removal of debris, supply of cutting tools, and support services like lubrication and cooling systems also play crucial roles in maintaining high-speed operations.

The speed of a Tunnel Boring Machine can vary widely depending on multiple factors. Engineers and operators must consider all aspects to optimize drilling rates while ensuring safety and efficiency throughout the tunnel construction process. Advances in technology continue to push the boundaries of what is possible, making TBMs increasingly effective tools for infrastructure development around the world.