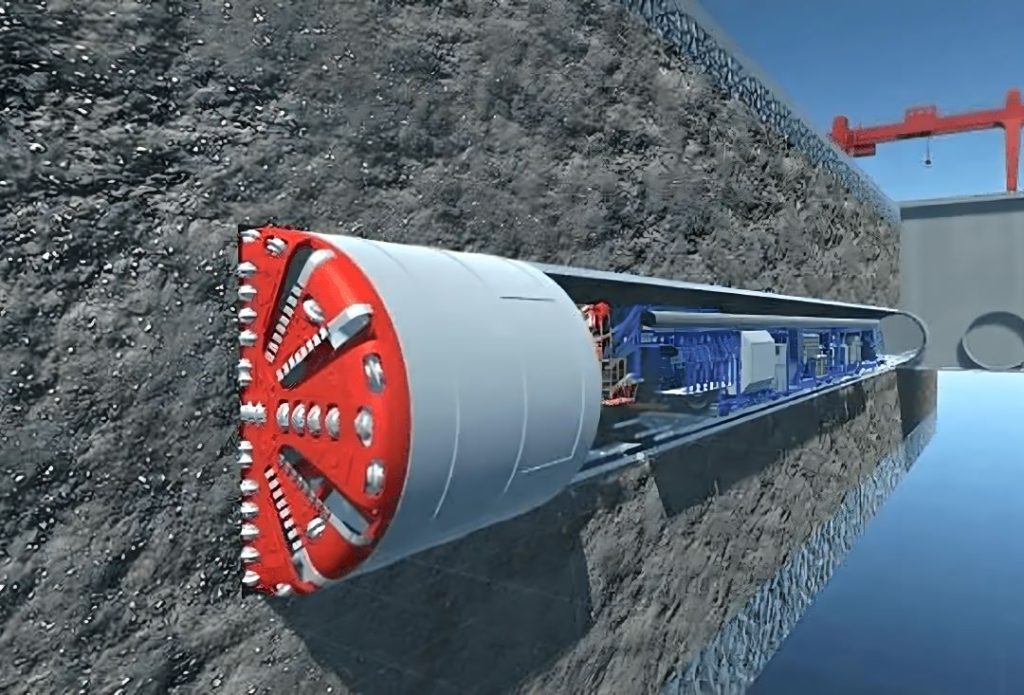

How does a tunnel boring machine turn? The turning of a tunnel boring machine (TBM) is a relatively complex process, mainly achieved through the following methods:

1、Adjusting the thrust of the propulsion cylinders

- Multiple propulsion cylinders are arranged around the body of the tunnel boring machine. When turning is required, the turning of the machine body is achieved by changing the thrust of the propulsion cylinders at different positions. For example, if you want the boring machine to turn left, you can appropriately reduce the thrust of the cylinders on the right side and increase the thrust of the cylinders on the left side. In this way, when the machine advances forward, a left-turning moment is generated, thus realizing turning.

- This method is similar to a car turning through a differential. The difference is that the boring machine changes the distribution of propulsion force by precisely controlling the pressure of each propulsion cylinder. Moreover, due to the huge size of the boring machine and the special working environment, extremely high control precision is required.

2、Utilizing the friction between the shield and the surrounding rock

- The shield of a shielded tunnel boring machine has a certain contact with the surrounding rock. During the turning process, the friction between the shield and the surrounding rock can be used to assist in turning. When adjusting the thrust of the propulsion cylinders to make the boring machine have a turning tendency, the friction between the shield and the surrounding rock can help stabilize the machine body and also guide the boring machine to turn in the expected direction to a certain extent.

- However, the utilization of this friction needs to fully consider the properties of the surrounding rock. If the surrounding rock is relatively fragile, it may not be able to provide sufficient friction and may even cause the surrounding rock to collapse due to excessive pressure; if the surrounding rock is too hard, it may cause greater wear to the shield.

3、Deflection control of the cutter head

- The cutter head of the boring machine plays a key role in the excavation process. Some advanced tunnel boring machines can perform slight deflection control of the cutter head. By adjusting the angle of the cutter head, a lateral component force is generated during excavation, thereby pushing the boring machine to turn.

- However, cutter head deflection control requires precise sensors and control systems. Because the main function of the cutter head is to crush rocks, if the deflection angle is too large or the control is improper, it will not only affect the turning effect but also may cause uneven force on the cutter head, accelerate the wear of the cutter head tools, and even damage the cutter head.