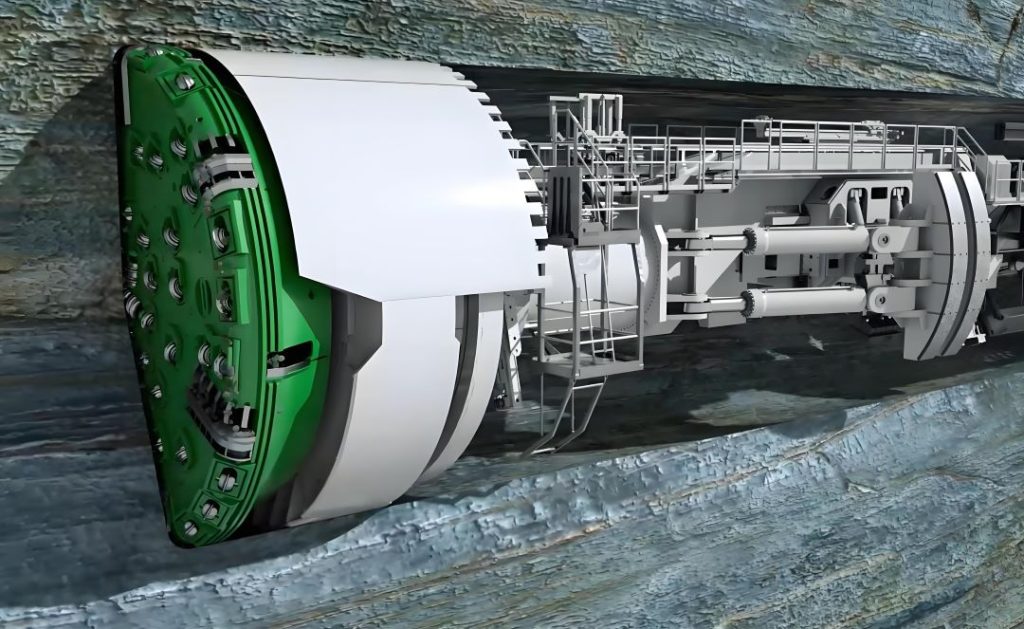

What is a tunnel drilling machine called? A tunnel drilling machine is commonly called a Tunnel Boring Machine (TBM). It is a sophisticated piece of equipment used to excavate tunnels through soil or rock, creating a smooth tunnel wall as it progresses. TBMs are highly efficient for large-scale tunneling projects, such as subway systems, railway tunnels, or utility conduits.

There are different types of TBMs designed for specific geological conditions, including:

- Earth Pressure Balance (EPB) TBMs: Ideal for soft ground conditions.

- Slurry TBMs: Used for waterlogged or unstable soils.

- Hard Rock TBMs: Designed for drilling through solid rock.

- Open-Face TBMs: Suitable for stable ground with minimal risk of collapse.

1. Earth Pressure Balance Shield (EPB) TBMs: These are ideal for soft ground conditions like clay and silt. They use rotating cutters at the front to excavate material while maintaining pressure behind the cutting face to prevent cave-ins.

2. Hard Rock TBMs: Also known as Disc Cutter TBMs, they feature large disc-shaped cutters that rotate against the rock surface, breaking it down into smaller pieces that can be removed by conveyors within the machine.

3. Mixed Ground TBMs: As the name suggests, these machines are capable of handling both hard rock and softer soils, making them versatile for unpredictable geological conditions.

4. Micro-Tunneling Machines: Smaller than standard TBMs, these are used for installing pipelines under sensitive structures where minimal disturbance is required.

5. Roadheaders: Though not exclusively used for tunneling, roadheaders are sometimes utilized for short-distance tunnel projects due to their maneuverability and versatility.

The operation of a TBM involves not only excavation but also the support of the newly created tunnel lining using precast concrete segments or sprayed concrete, ensuring stability and safety during and after construction. The advancements in TBM technology have significantly reduced the time and cost associated with tunnel construction, revolutionizing infrastructure development around the world.