Full-face tunnel boring machine (TBM) and partial-face tunnel boring machine (Partial-Face Excavation Machine) are two main mechanical equipment used for tunnel excavation. The differences in their application are mainly reflected in the following aspects:

Difference 1. Excavation method

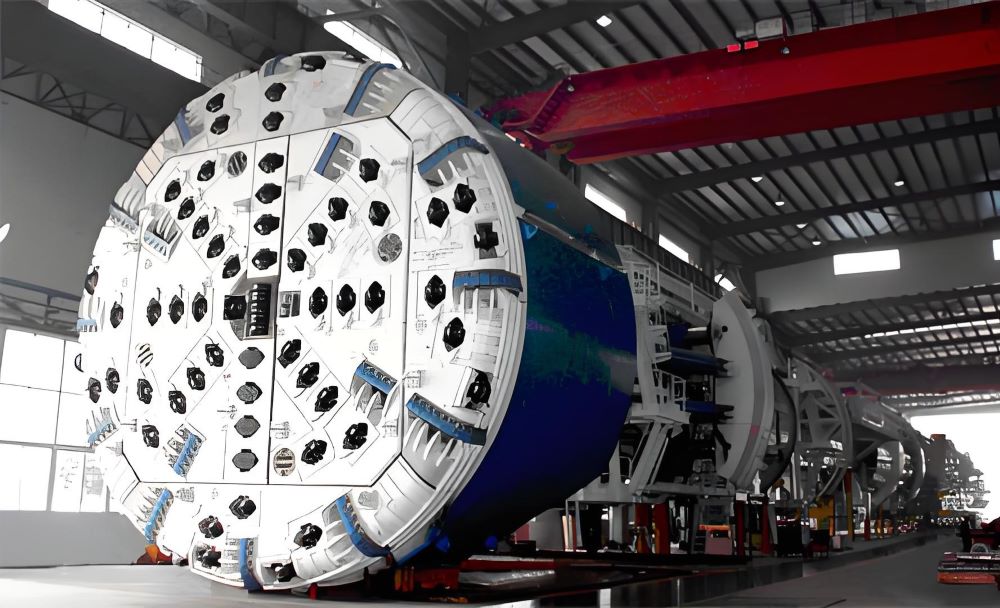

Full-face tunnel boring machine:

A full-face tunnel boring machine refers to a machine that can excavate the entire section of a tunnel at one time. It usually uses a circular cutterhead to cut rock or soil by rotating the cutterhead, and transports the excavated soil out of the tunnel through a conveying system.

It is suitable for long-distance, continuous tunnel engineering, especially when the geological conditions are relatively stable.

Partial-face tunnel boring machine:

A partial-face tunnel boring machine refers to a machine that can gradually excavate the tunnel section. It usually uses a variety of construction methods, such as drilling and blasting, partial mechanical excavation, etc.

It is suitable for tunnel engineering with short distances, complex geological conditions, and irregular cross-sectional shapes.

Difference 2. Scope of application

Full-section TBM:

Applicable to tunnels with relatively uniform geological conditions and regular tunnel cross-sections (generally circular or elliptical), such as urban subway tunnels, highway tunnels, etc.

For projects that require long-distance, continuous construction, full-section TBMs are more efficient.

Partial-section TBM:

Applicable to tunnels with complex geological conditions and irregular cross-section shapes, such as mine tunnels, underground projects with non-circular cross-sections, etc.

When geological conditions are changeable or there are many faults, caves and other complex situations, partial-section TBMs can respond more flexibly.

Difference 3. Construction efficiency

Full-section TBM:

Since it can complete the excavation of the entire section at one time, the construction efficiency is high, but the equipment investment and maintenance costs are also relatively high.

Partial-section TBM:

The construction speed is relatively slow, but it can better adapt to geological changes, has strong flexibility, and the equipment investment and maintenance costs are relatively low.

Difference 4. Construction cost

Full-face TBM:

The initial investment is large and the equipment cost is high, but the construction cost per unit length is low in long-distance and large-scale projects.

Partial-face TBM:

The initial investment is relatively low, but due to the slow construction speed, the overall construction time may be longer, thereby increasing the total cost.

Difference 5. Impact on the environment

Full-face TBM:

The disturbance to the surrounding environment during construction is relatively small, especially suitable for underground construction in cities, reducing the impact on ground traffic and buildings.

Partial-face TBM:

More vibration and noise may be generated during construction, and the disturbance to the surrounding environment is relatively large, but under certain complex geological conditions, it can better protect the surrounding environment and structures.

Full-face TBM and partial-face TBM have their own advantages and disadvantages in the application of tunnel excavation. The specific choice of equipment depends on many factors such as the geological conditions of the project, tunnel length, cross-section shape and construction cost.