In recent years, my country has implemented the concept of sustainable development and promoted the construction industry to develop in an efficient, green, sustainable and technological way. The "14th Five-Year Plan" clearly states that it is necessary to strengthen infrastructure construction, improve the quality and efficiency of engineering construction, and promote green development. At the same time, the "Guiding Opinions on Accelerating the Construction of New Infrastructure" emphasizes the key role of scientific and technological innovation in engineering construction, and encourages enterprises to increase investment in research and development and actively apply advanced technologies and equipment.

Against this background, Lanhi has a deep insight into market demand, and with a high sense of responsibility and mission, has invested a lot of resources in research and development. In order to adapt to the various methods of tunnel excavation design, LZ212A two boomer drilling jumbo came into being! It can not only meet the full-section and multi-step synchronous excavation operations at the same time, but also the drill arm can reach a step depth of 10m, solving the problem that the drill arm of traditional rock drilling equipment is "short" and cannot meet the step spacing. It can also meet the system anchor, lock-foot anchor, advance small guide tube, grouting hole and other rock drilling operations, and the drilling depth can reach 5.1m.

I. Introduction of LZ212A two boomer drilling jumbo

01 Technical parameters and operating scope

◾Transportation dimensions (length x width x height): 18200×2900×3660mm

◾Machine weight: 40t

◾Operating range (width x height): 16mx12m

◾Single-rod drilling depth scale: 5.1m

◾Working mode: electric construction + diesel emergency

◾Control mode: local operation + wireless remote control

◾Boom mode: double triangle self-balancing

◾Drive and steering mode: four-wheel drive, rear axle steering

◾Applicable working conditions: various rock drilling operations in full-section excavation or step excavation of tunnel inverts in underground projects such as highways, railways, water conservancy and hydropower, and national defense

02 Core configuration

1. Adopting 125kW Cummins diesel engine that meets the National IV emission standard, it has strong power, high efficiency, long service life and cleaner construction.

Cummins diesel engine

2. The chassis is rigid and durable, equipped with a heavy-duty wet bridge, which provides stable guarantee for the driving and operation of the equipment. At the same time, it is equipped with a variety of braking systems such as driving brake, parking brake, emergency brake, etc., which greatly improves the overall reliability of the equipment.

Rigid integrated chassis + heavy-duty wet bridge

3. Self-set electric anti-stuck drill function to increase the service life of drilling tools and reduce equipment maintenance costs. Optional dual-mode operating system, local operation is reliable and has a wide field of view; wireless remote control construction has a good line of sight, and positioning is convenient and fast. The combination of the two is flexible and convenient to operate.

Liftable operating table + ceiling

4. The boom adopts a double triangle self-balancing mode. Through the principle of dynamic double triangle, the equipment can maintain a good balance during operation, reduce shaking or tilting caused by imbalance, and thus improve the stability of the operation.

Double triangle self-balancing mode

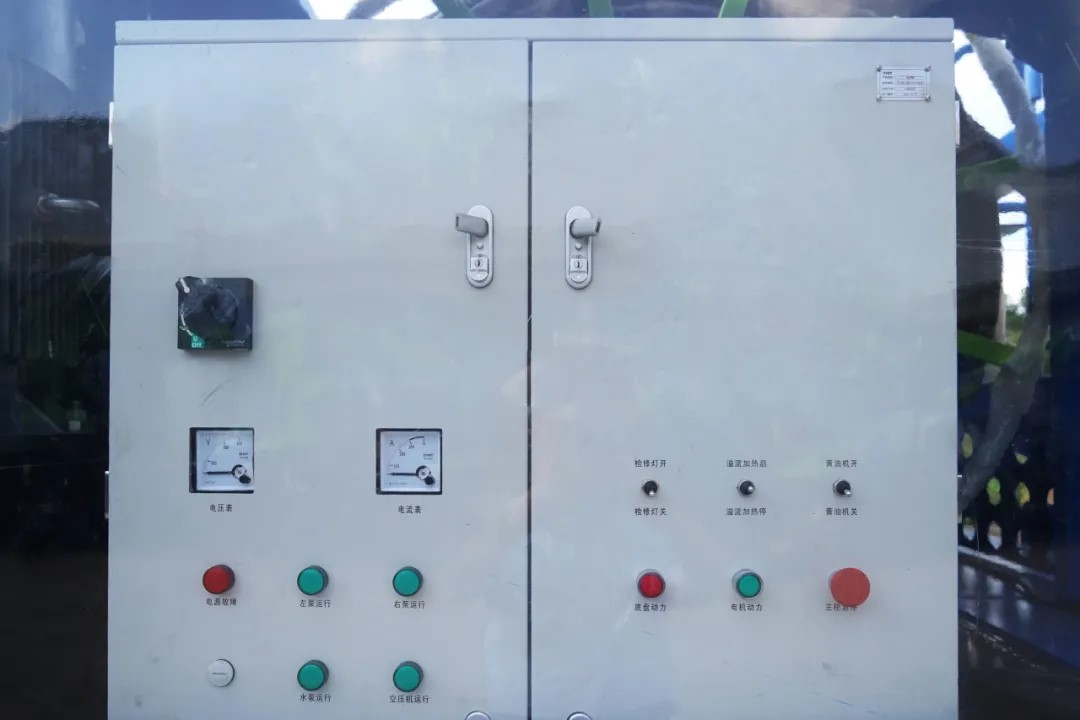

5. It adopts electric control technology, with remote monitoring program, GPS positioning and MQTT data transmission and reception, drilling depth detection, water pump flow and pressure detection, electric anti-stuck drill and other functions. For example, during construction, the water pump flow and pressure can be detected to clean the hole in time to ensure that there is no residue in the hole that affects the subsequent construction, so that the drilling quality is higher.

Electronic control technology box

II. Significant features

01 One machine with multiple functions, more comprehensive

LZ212A two boomer drilling jumbo is widely applicable and comprehensive. Its operating range can reach 16m×12m, which meets the full-section, two-step and three-step synchronous excavation operations. The drill arm can reach a total step depth of 10m, which meets almost all rock drilling operations such as system anchors, locking foot anchors, advanced small guide tubes, grouting holes, etc., and the drilling depth can reach 5.1m.

02 Reliable performance, more humanized

LZ212A two boomer drilling jumbo adopts a control method that combines local operation with wireless remote control. The operating table can be raised and lowered, and the dual operating positions can be mutually assisted. At the same time, it is equipped with a powerful power system-Cummins engine, with an engine power of 125kW, National IV emission standards, large power output and high efficiency.

Four-wheel drive, rear axle steering, equipped with heavy-duty wet bridge, also equipped with service brake, parking brake and emergency brake, providing multiple guarantees for construction. Equipped with automatic anti-stuck drill, automatic drilling and retracting functions, the whole machine has reliable performance, accurate positioning, fast drilling speed and low drilling tool consumption.

03 Green energy saving, more sense of mission

In terms of energy saving, the LZ212A two boomer drilling jumbo has an electrical installed power of 132kW, and the working mode is electric operation plus diesel emergency, which effectively reduces energy consumption. In terms of green protection, the Cummins engine with National IV emission standards makes construction cleaner and reduces the pollution of exhaust emissions to the environment. In infrastructure construction projects, the low-emission feature can greatly reduce the impact on the surrounding environment and residents' lives, which also reflects Lanhi's responsibility and mission.