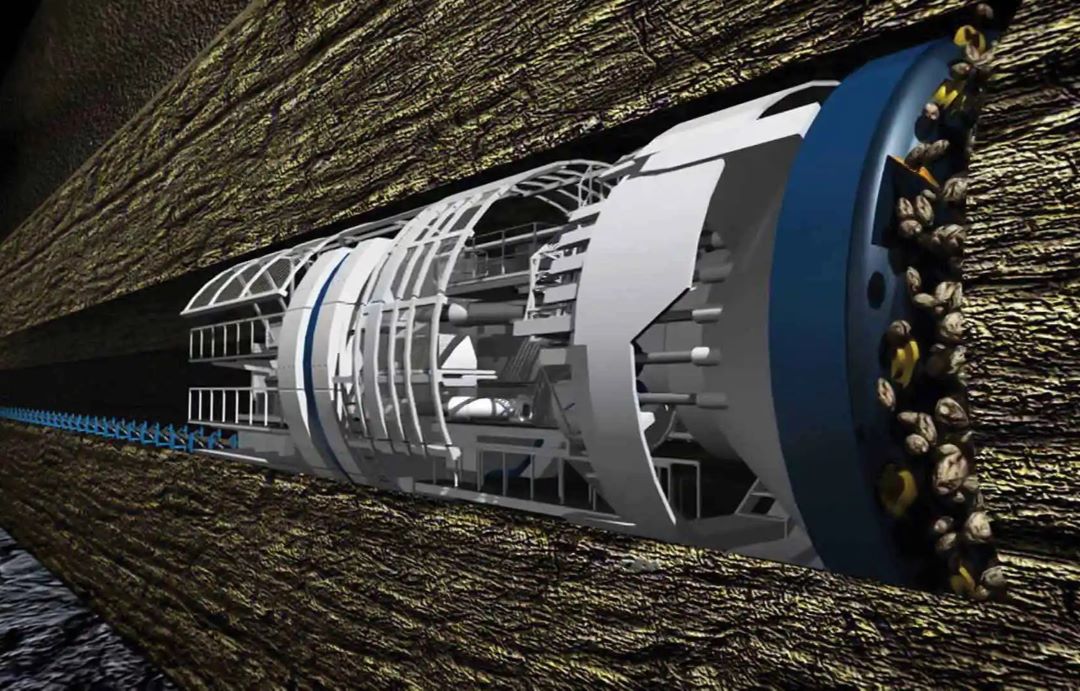

To ensure the quality and efficiency of Tunnel Boring Machine (TBM) construction, the following measures can be implemented:

1. Strict Control of Design Parameters: During the selection and design stages of TBM, factors such as geological conditions, tunnel dimensions, and construction environment should be thoroughly considered. This helps in reasonably determining the TBM model, specifications, and technical parameters, ensuring that the TBM performs optimally under complex and changing geological conditions during construction.

2. Optimization of Construction Process Flow: A scientifically sound construction process should be developed based on geological conditions and construction requirements. For example, the sequencing of TBM operations such as start-up, shutdown, turning, and tool replacement should be planned efficiently, as well as coordinating the use of other construction equipment to improve overall construction efficiency and quality.

3. Strengthening On-Site Management: Effective on-site management is a crucial factor in ensuring the quality and efficiency of TBM construction. A well-established on-site management system should be put in place, with clear responsibilities and authorities for each level of personnel to ensure that all on-site tasks are carried out in an orderly manner. Additionally, strict safety supervision should be enforced to prevent accidents.

4. Strengthening Equipment Maintenance: Regular maintenance of the TBM is essential to detect and address any faults or hidden risks promptly. A detailed maintenance and operation plan should be formulated to ensure the TBM remains in good working condition. Moreover, managing spare parts and consumables efficiently ensures timely replacement when needed.

5. Improving Operator Skills: Operators are one of the key factors affecting TBM construction quality and efficiency. Training and assessment programs should be implemented to enhance the operators' skills and abilities. Operators should become familiar with the structure, working principles, and operating procedures of the TBM, enabling them to handle various emergencies competently.

6. Strengthening Communication and Coordination with the Design Team: Maintain close communication with the design team to promptly report any issues or difficulties encountered during construction. Necessary adjustments and optimizations should be made to the design plans based on actual conditions, ensuring that the design aligns with the practical needs of construction.

7. Incorporating Information Technology: Information technology can be used to improve the management level and efficiency of TBM construction. For instance, information management systems can be employed to monitor and manage construction progress, equipment status, material consumption, etc., in real-time. Additionally, Building Information Modeling (BIM) technology can be utilized for visual simulation and optimization of the construction process.

By implementing these measures, the quality and efficiency of TBM construction can be effectively ensured, facilitating the smooth progress of tunnel engineering projects.