What is a Roadheader? A roadheader is a heavy-duty excavation machine primarily used in underground mining, tunneling, and civil engineering projects. It is designed to cut through hard rock, coal, or other geological formations while simultaneously collecting and transporting debris. Its design allows it to efficiently remove material from soft to medium-strength rock and coal seams without the need for drilling and blasting.Roadheaders are widely employed in coal mines, road tunnels, subway constructions, and hydraulic engineering due to their efficiency in confined spaces and adaptability to varying ground conditions.

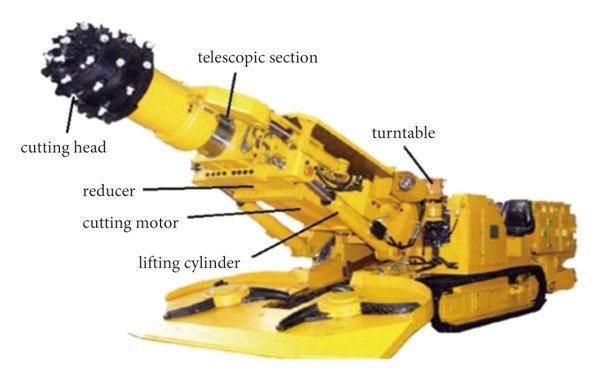

Below is a breakdown of its main components:

1. Cutting Head

- Function: The cutting head is the workhorse of the machine. It rotates (either transversely or longitudinally relative to the boom) and is equipped with cutting tools such as picks, disc cutters, or specialized bits that break the rock.

- Variations: Depending on the application, the cutting head may be designed for milling (boring action) or ripping (slicing action), which influences the orientation and motion of the head.

“A roadheader is a piece of excavating equipment consisting of a boom-mounted cutting head, a loading device (usually involving a conveyor), and a crawler travelling track...” citeturn0search0

2. Boom (Cutting Arm)

- Function: The boom or cutting arm supports the cutting head and provides the necessary reach and flexibility to position the head against the rock face. It enables the operator to adjust the angle and depth of the cut.

- Mechanics: The boom is typically operated via hydraulic cylinders, which allow for adjustments in height and angle during the excavation process.

3. Loading System

- Components: Most roadheaders incorporate an onboard loading device—often a conveyor or chain system—that immediately collects and transports the excavated material from the cutting head to a collection area or transport vehicle.

- Benefits: This integrated system increases productivity and minimizes the need for secondary handling equipment.

4. Mobility and Undercarriage

- Tracks/Crawlers: The machine is mounted on crawler tracks that provide stability and mobility in the confined and uneven conditions of underground environments.

- Drive System: Power from hydraulic or electric motors drives both the cutting head and the tracks, ensuring coordinated movement and excavation.

5. Hydraulic and Electrical Systems

- Hydraulic Components: A network of hydraulic pumps, cylinders, and valves operates the boom, the cutting head, and sometimes even the loading system. These systems allow for precise control over the machine’s operations.

- Electrical Controls: Modern roadheaders come with integrated control panels and electronic systems that help monitor performance, adjust operating parameters, and ensure safety during excavation.

Roadheaders are indispensable in modern tunneling and mining, combining mechanical power with precision engineering. Their modular design allows customization for specific projects, ensuring efficiency and safety in demanding environments.