What is tunnel boring machine? A tunnel boring machine (TBM) is a large piece of machinery used for excavating tunnels.

TBMs are typically cylindrical in shape and are equipped with a rotating cutting head that breaks up rock and soil as the machine moves forward. The excavated material is then removed through a conveyor system. TBMs can be used to create tunnels for a variety of purposes, including transportation (such as subways and railways), water and sewage systems, and mining.

These machines are highly specialized and can operate in different types of geological conditions. They offer several advantages over traditional tunneling methods, including greater speed, precision, and safety.

TBMs are comprised of several critical components that work together to facilitate the digging process:

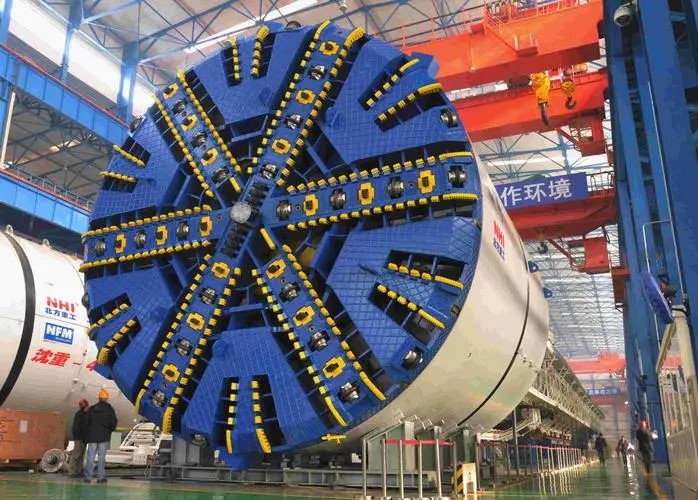

1. Cutting Head: Located at the front of the TBM, this part contains rotating blades or disks that break through the ground material. The design of the cutting head can vary depending on the type of soil or rock being excavated.

2. Shield: The shield surrounds the cutting head, providing support to the newly excavated tunnel face and protecting the TBM’s internal systems from collapse.

3. Gantry Cranes: These are used for moving materials such as concrete segments inside the tunnel for lining purposes.

4. Conveyor System: Excavated material is removed via a conveyor belt system that transports it back to the surface.

5. Support Systems: TBMs include advanced support mechanisms like hydraulic jacks and grouting systems to stabilize the tunnel walls immediately after excavation.

6. Service Tunnel: A small secondary tunnel runs parallel to the main one, facilitating the movement of personnel and equipment needed for maintenance and operations.

Type of tunnel boring machine

1. Earth pressure balance (EPB) TBM: Used in soft ground and soil conditions. It balances the pressure of the excavated material to maintain stability.

2. Slurry TBM: Suitable for soft ground and water-bearing formations. It uses a slurry to support the tunnel face and remove excavated material.

3. Soft Ground TBMs: Designed for soils and clays where the terrain may be less stable.

4. Hard rock TBM: Designed for excavating through hard rock formations. It has powerful cutting tools and a robust structure.

5. Double shield TBM: Can be used in both hard and soft ground conditions. It has two shields for different stages of tunneling.

6. Mixed Ground TBMs: Capable of handling both hard rock and soft ground within the same tunnel project.

How a tunnel boring machine works?

1. Excavation: The TBM uses a rotating cutterhead equipped with cutting tools to break up the soil or rock at the tunnel face. The cutterhead is powered by a motor and rotates at a high speed to cut through the material.

2. Removal of excavated material: As the cutterhead cuts through the material, the excavated soil or rock is removed from the tunnel face and transported to the rear of the TBM. This is typically done using a conveyor belt or other material handling system.

3. Support of the tunnel walls: To prevent the tunnel walls from collapsing, the TBM may use various methods of support, such as installing steel ribs, spraying concrete, or using a combination of both.

4. Advancement of the TBM: Once the tunnel face has been excavated and the walls supported, the TBM is advanced forward. This is typically done by using hydraulic cylinders or other means of propulsion to push the TBM along the tunnel axis.

5. Monitoring and control: Throughout the tunneling process, the TBM is monitored and controlled by a team of operators. They use a variety of sensors and instruments to monitor the TBM's performance, including its speed, torque, and pressure. They also use cameras and other monitoring equipment to keep an eye on the tunnel face and ensure that the excavation is proceeding as planned.

Advantages of Using TBMs

The use of TBMs offers numerous advantages over traditional tunneling methods:

- Safety: Minimizes risks associated with manual labor in hazardous environments.

- Efficiency: Can excavate large sections quickly and continuously, reducing overall construction time.

- Precision: Provides accurate control over tunnel dimensions and alignment.

- Environmental Impact: Reduces surface disruption by operating underground.